Our Optimization Framework

Re:Shape’s framework delivers sustainable and efficient transformation, enabling clients to maximize value and remain competitive in the marketplace through innovative solutions.

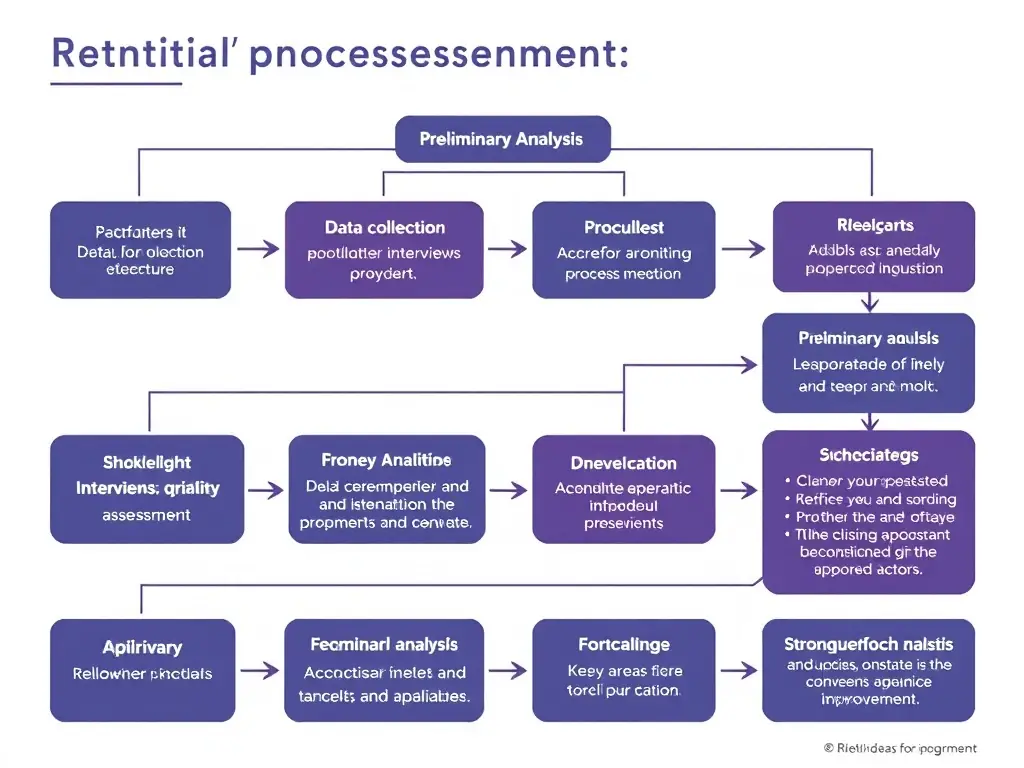

Understanding Our Process Optimization Framework: A Step-by-Step Guide

This involves examining your existing processes to identify inefficiencies, bottlenecks, and areas for improvement. Think about techniques like Lean, Six Sigma, or Kaizen which focus on continuous improvement and waste reduction. The goal is to enhance productivity, reduce costs, and improve quality

Identify Key Processes

Set Improvement Goals

Analyze Current Performance

Select Improvement Techniques

Choose the most appropriate techniques for your situation. Here are a few options:

Lean

Focuses on eliminating waste (anything that doesn’t add value) and improving flow. Common tools include 5S (Sort, Set in order, Shine, Standardize, Sustain), Kanban, and Just-In-Time (JIT) production.

Six Sigma

A data-driven approach that aims to reduce variation and defects in processes. It uses DMAIC (Define, Measure, Analyze, Improve, Control) methodology and statistical tools to drive improvements.

Kaizen

Emphasizes continuous, incremental improvements. Encourages employee involvement and regular feedback loops to drive ongoing enhancements.

Implement Changes:

Monitor and Sustain

Examples of Tools and Techniques:

Value Stream Mapping

A tool used to visualize and analyze the flow of materials and information required to bring a product or service to a customer.

5S (Sort, Set in order, Shine, Standardize, Sustain)

A workplace organization method that uses a list of five Japanese words: seiri (sort), seiton (set in order), seiso (shine), seiketsu (standardize), and shitsuke (sustain). It helps create a clean, organized, and efficient work environment.

DMAIC (Define, Measure, Analyze, Improve, Control)

A Six Sigma methodology used to improve existing processes. It involves defining the problem, measuring key aspects, analyzing data, improving the process, and controlling.